Corrugated Materials

Kongsberg cutting tables offer state-of-the-art tools for cutting and creasing corrugated materials.

Digital cutting machines have revolutionized the way manufacturers work with materials. Choosing the right material for your application can make a significant difference in production speed, cut quality, and cost-efficiency. This is especially true for materials like corrugated cardboard, which presents unique challenges and opportunities for cutting technologies.

Corrugated cardboard is one of the most widely used materials in packaging, but it brings several challenges when cut digitally. The variability in thickness, the type of flute, and moisture content can all affect the cutting process. In addition, the flexibility of corrugated material often results in inconsistent edges and cutting performance.

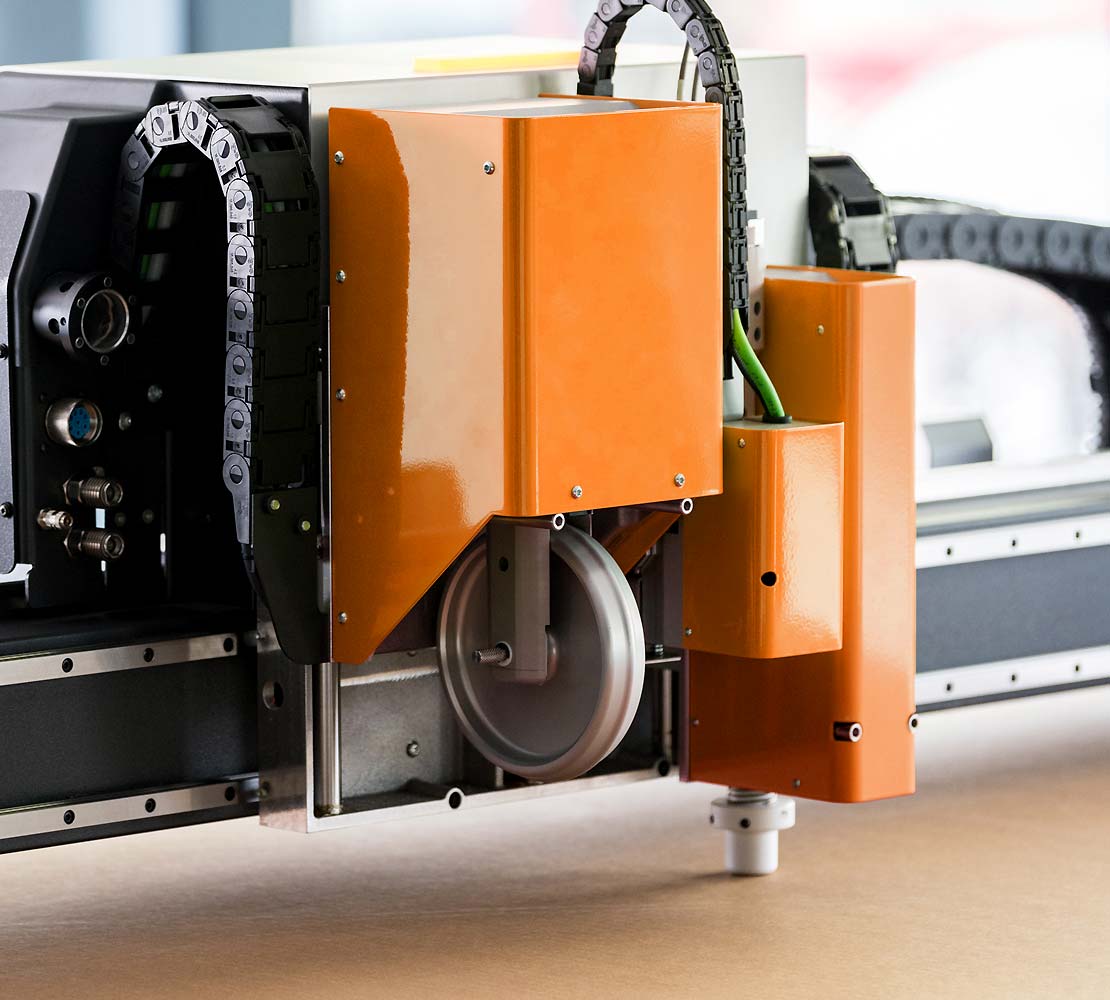

The Kongsberg Ultimate sets a new benchmark in corrugated and display manufacturing. Designed with advanced engineering, this cutting table achieves exceptional accuracy at industry-leading speeds, boasting up to 2.7G acceleration and peak cutting rates exceeding 165 m/min.

It marks a major technological advancement, purpose-built to meet the demanding needs of corrugated converters who manage continuous, high-volume, multi-batch workflows.

The Kongsberg C Series empowers corrugated converters with the adaptability required to excel in a fast-paced market. Designed to process everything from rugged board to delicate display substrates, it delivers accuracy and dependability on every project.

Its sturdy build, rapid throughput, and extensive tooling portfolio support efficient production across a variety of uses.

From packaging prototypes and custom short runs to standout displays, the C Series enables you to tackle diverse jobs with confidence, helping your business thrive and grow.

The Kongsberg X Series delivers rapid and precise cutting for corrugated prototypes and short production runs. Robust, accurate, and user-friendly, it keeps your workflow smooth while maintaining high standards of quality across a variety of board materials.

Engineered for future growth, the X Series makes it easy to enhance your capabilities as your business develops. You can introduce automation, upgrade tools, or move to larger formats at your own pace: no need for a new table. It’s the intelligent, adaptable solution for corrugated converters seeking reliable performance now and scalability for the future.

Selecting the right tooling is critical for achieving clean, accurate cuts and reliable results when working with corrugated board. Purpose-built tools are designed to handle the unique structure of corrugated, from single-wall to double-wall and heavy-duty grades, ensuring crisp edges and minimizing the risk of crushed flutes.

By using solutions engineered specifically for corrugated applications, operators can improve cut quality, boost productivity, and extend the lifespan of both tools and materials, no matter how demanding the production run.

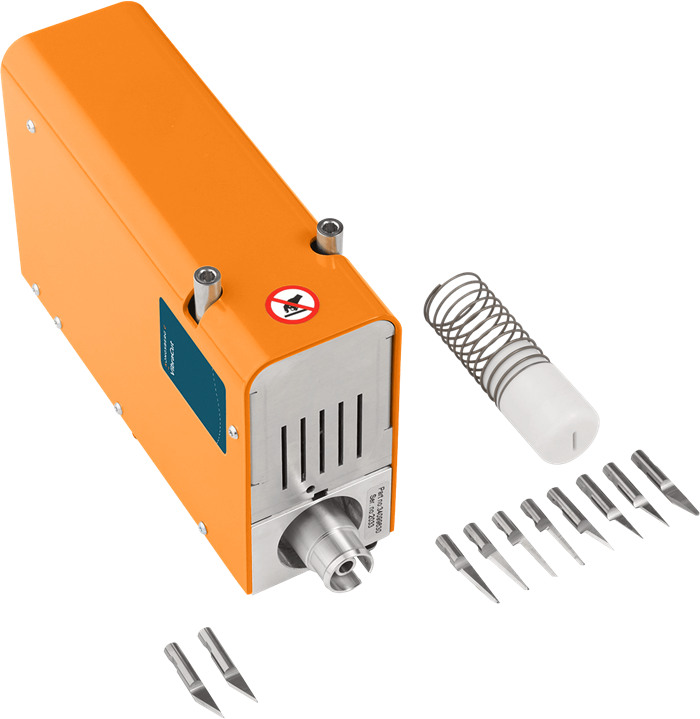

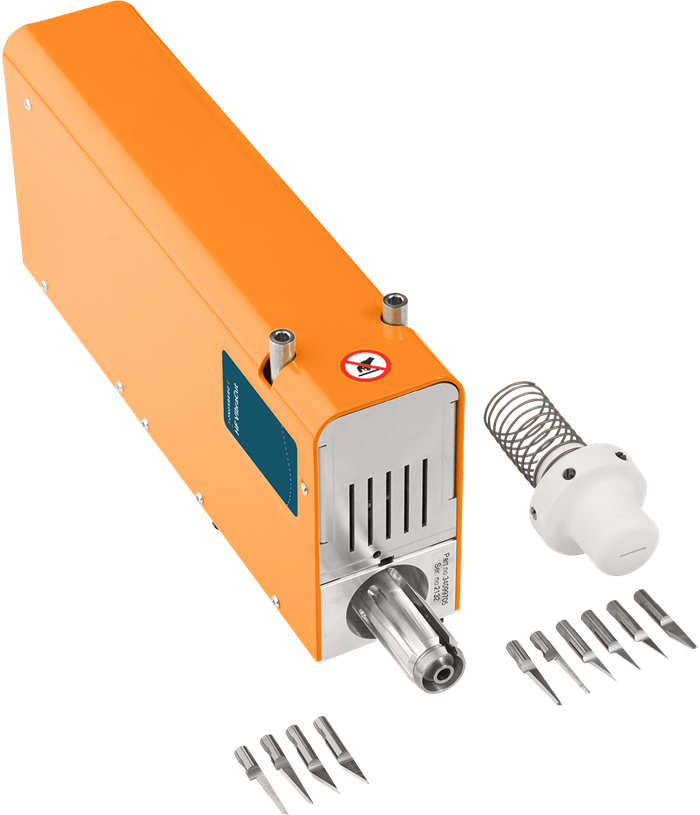

The CorruSpeed Tool is developed for cutting corrugated board at high speeds without oscillating but brings amazing benefits for cutting textile material as well.

The CorruSpeed operates with a crushing cup, which in combination with controlled down pressure makes it possible to use a drag knife without tearing or cracking the liner.

The Dual Heavy Duty Unit makes it possible to cut, crease and perforate a single job without the need to change tools. There’s no manual operator intervention for tool changes, which means you can save time.

The unique 50 kg crease wheel downforce is unrivalled on double and triple wall corrugated materials. The unit offers best-in-class crease quality, even on materials with a high recycled material content.

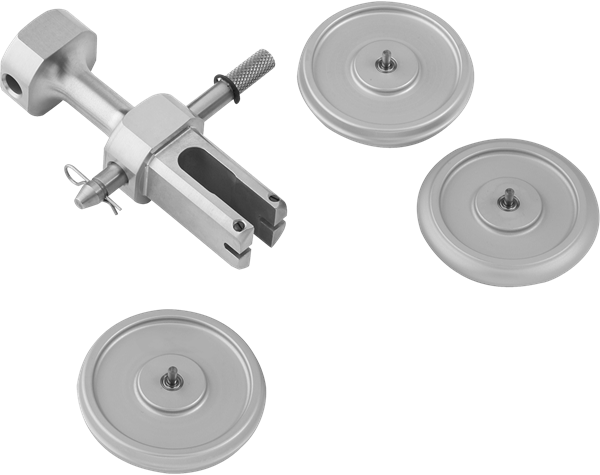

The Crease Wheels offers the possibility to crease most corrugated thicknesses.

The medium-size 60 mm (2.4”) wheels also allow for creasing with a higher pressure without cracking the liner, and with a limited over-crease. The 150 mm (6“) diameter crease wheels come with a scoring pressure equivalent to 50 kg.

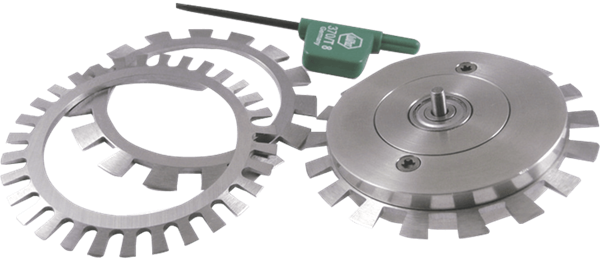

The Perforation Wheel pack offers the possibility to produce tear perforations at high speeds for corrugated board up to C flute (4 mm).

This tool is suitable for cutting single and double wall corrugated board and other light-duty fibrous materials, such as corrugated board, soft foam board and corrugated plastic.

It runs at a frequency of 6,000 Strokes per minute and with an amplitude of 0.3 mm. These properties, along with a powerful motor, enable cutting at full table speed with good quality materials.

This tool is suitable for cutting single, double wall, triple wall corrugated and paper core boards up to 20 mm and other light-duty fibrous materials, such as corrugated board, soft foam board and corrugated plastic. It runs at a frequency of 12,000 strokes per minute and amplitude of 1.2 mm.