Aluminum & ACM

Kongsberg tables have powerful tools to produce jobs on aluminum or Aluminum Core Material like Dibond, Red Bond, HiLite.

Digital cutting tables are redefining how manufacturers and sign makers process alumnium and aluminum composite materials (ACM). While these materials offer exceptional strength and flexibility for a range of industrial applications, they also introduce specific challenges, such as maintaining clean edges, minimizing tool wear, and handling diverse material thicknesses with accuracy.

In today’s competitive B2B environment, businesses require solutions that combine speed, reliability, and high-quality results. Advanced digital cutting systems are designed to overcome these obstacles, streamlining workflows and ensuring consistent, precise cuts for aluminum and ACM projects.

The Kongsberg C Series empowers manufacturers to achieve precise, clean cuts in aluminum and aluminum composite materials (ACM). Designed to tackle the unique demands of rigid metals and composites, it combines sturdy construction with advanced digital control for consistent results, even on challenging jobs.

Engineered for high productivity, the C Series offers a suite of specialized tools and delivers stable, accurate processing at speed. From intricate signage to durable industrial components, this solution enables you to confidently take on a wide variety of aluminum and ACM projects, streamlining operations and supporting your business growth.

The Kongsberg X Series offers fast, precise cutting for aluminium and aluminium composite materials (ACM), making it ideal for prototyping, signage, and custom fabrication. Engineered for strength and accuracy, the X Series ensures reliable results even on complex or short-run jobs, all while remaining intuitive and easy to operate.

Designed to evolve with your production needs, the X Series allows you to upgrade tooling, introduce automation, or scale to larger formats over time: no need to replace your entire system. It’s the flexible solution for manufacturers who demand top performance with the freedom to adapt as their business grows.

Choosing the right tooling is essential for achieving high-quality results when processing aluminum and aluminum composite materials (ACM). Specialized tools help maximize efficiency, maintain edge integrity, and deliver smooth finishes across a range of applications.

By selecting equipment tailored to the unique properties of these materials, operators can unlock greater precision, extend tool life, and ensure consistent performance, no matter the complexity of the task.

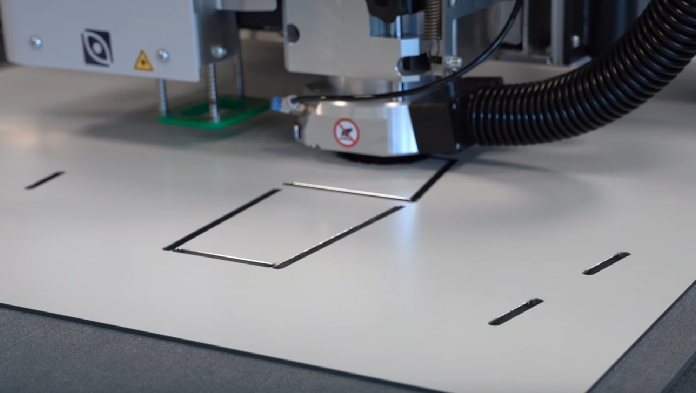

The High-Power Milling Unit on the Kongsberg C table and the MultiCUT-HP tool head on the Kongsberg X table allow for milling, contour cutting, routing, drilling and engraving.

It’s suitable for high speed routing in a wide range of materials such as foamed PVS, solid PVC/PS, acrylic, aluminium composite material (ACM), MDF, wood, ...

The 3kW milling spindle offers fast feed rates, which considerably widens the bottleneck that routing jobs often present. The spindle features a 3kW of milling power and speeds up to 60,000 RPM. It is liquid cooled in order to utilize its full power potential.

LubriCool is an option to cool the milling bit and lubricates the routing process. It results in significantly higher productivity and extends the life length of the milling bits for materials such as Aluminum composite Material (ACM) and some aluminum alloys.

The Braille Tool enables the application of raised dots used in Braille, the tactile writing system people that are blind or visually impaired. Various government regulations make this tool necessary throughout the world. The Braille tool inserts spheres into predrilled holes in rigid materials.

Get in touch with one of our experts. We're here to help you cut smarter, faster and better.