Features

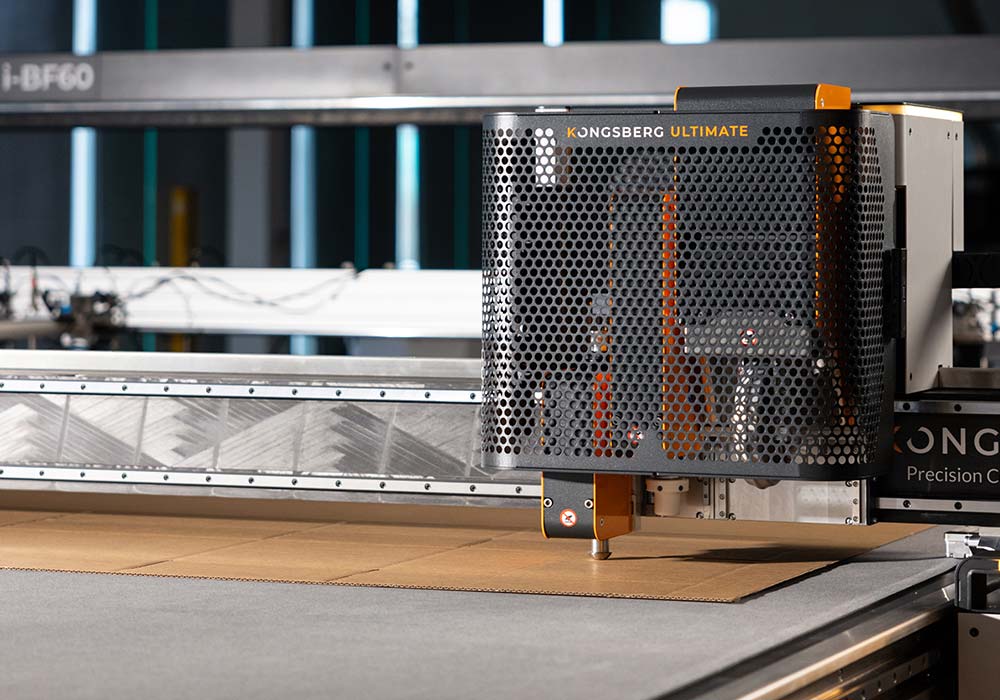

The Kongsberg Ultimate cutting system boasts a number of innovative features that make dedicated corrugated cutting a breeze.

For bulk corrugated production, it's the swiftness of acceleration that takes the crown over mere top speed. In multi-batch continuous production, quick acceleration is the key to efficiency.

This game-changing direct drive technology propels the Kongsberg Ultimate with up to 2.7G acceleration and delivers peak cutting speeds of over 165 m/min.

What’s more, it brings a reduction in noise, providing a quieter, more comfortable working environment.

The wide-format traverse beam on the 64 & 66 tables is meticulously designed, woven from a single filament of carbon, wound around a proprietary internal structure for ultimate strength and light weight.

This ensures minimal twisting and bending of the beam even under the acceleration forces and 50 kg down-force needed for optimal creasing.

The first zone slows the machine (e.g. when an operator comes closer for a visual inspection) ensuring uninterrupted output. Move even closer, and the second zone pauses everything. This way, unnecessary production stops are minimized, boosting overall productivity.

Vibrant LED indicators (Red/Green/Orange) communicate machine status from any viewpoint, making operations transparent and safe.

With our advanced safety features, the machine remains highly accessible even when operating at full speed, guaranteeing the operator's protection at every moment.

Achieve the trifecta of cutting, creasing, and perforating of corrugated jobs without halting for operator interventions or tool adjustments, thanks to our Dual Heavy-Duty Unit combined with a CorruSpeed tool and oscillating VibraCut Knife tools.

Furthermore, existing Kongsberg C Series corrugated tools integrate seamlessly with the Kongsberg Ultimate platform.

In iPC 3.0, the new sequencing module has a state-of-the-art algorithm at heart that optimizes cutting routes for faster and more efficient production.

On its own, the Kongsberg Ultimate excels with a 31% productivity increase over Kongsberg’s previous best. When paired with the Intelligent sequencing module, this figure can skyrocket to a staggering 57% more productivity.

The Kongsberg Ultimate supports your ideal configuration: from manual, to semi-automated with a Feeder & Stacker, right up to the pinnacle of automated production with the Robotic Material Handler. Every integration is smooth, boosting your operation's efficiency.

The beauty of Kongsberg Ultimate platform is its incremental investment potential. As your requirements evolve, the Kongsberg Ultimate adapts, ensuring you always have the best fit.

The Kongsberg Ultimate comes with a brand-new workstation with an adjustable worktop, convenient storage trays, and even a Qi phone charger.

A new touchscreen, large and intuitive digital buttons, an integrated storage system and a dedicated bin for used blades deliver an ergonomic, user-friendly experience for the operator.

The Kongsberg Ultimate is flexible by design. It can be tailored to align with any environment, ensuring optimal alignment with your specific needs and layout.

Interested in experiencing the future of corrugated cutting? Get in touch with us and have a chat with our industry experts.