Benefits

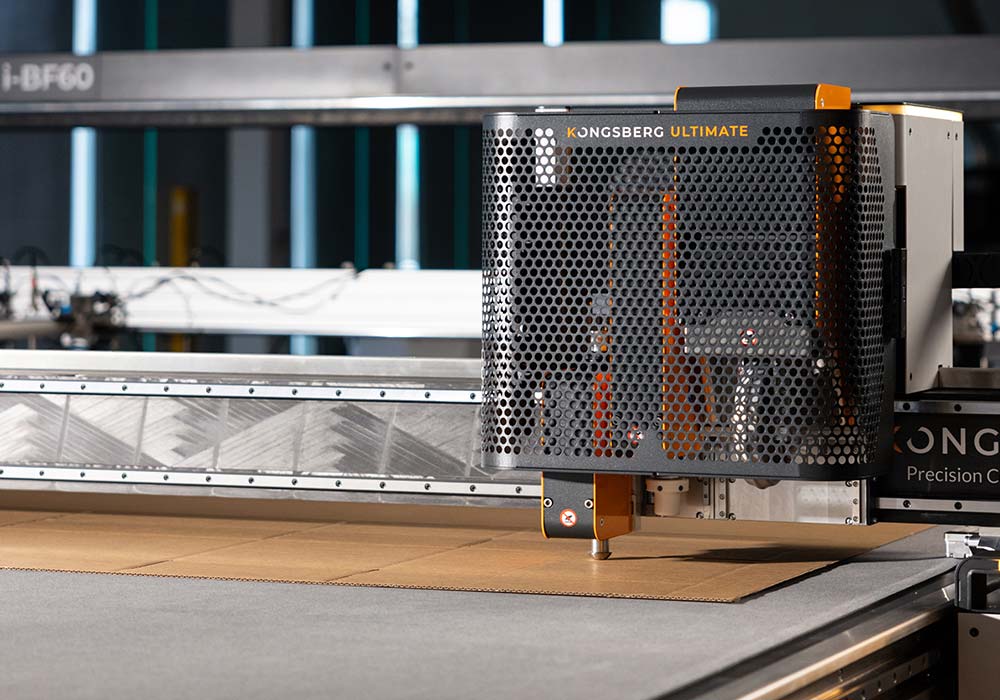

Find out why Kongsberg Ultimate is the perfect cutting solution for corrugated and display production.

The Kongsberg Ultimate was designed and engineered from the ground up to do one thing well: make corrugated cutting as productive as possible. Every aspect of the table supports that goal:

The innovative traverse beam on our wide-format tables (64 & 66), offers a continuous 50 kg downforce for precise and consistent creasing. This design, paired with the capability to easily handle a 2.5G force, ensures every cut is just as precise as the last.

The Kongsberg PrecisionDrive™ system promises precise motion every time. By integrating an infinite linear, high-torque motor with a rack and pinion setup, your cuts are smooth, accurate, and dependable.

The Kongsberg Ultimate comes with dedicated heavy-duty tooling for corrugated production. This means continuous cutting with diverse capabilities - from cutting to creasing to perforating - all without the hassle of switching tools.

Thanks to a drive system design without gearbox, you can expect more productivity between servicing intervals and less downtime. The Kongsberg Ultimate's overall design optimizes maintenance and breaks. The fewer parts mean less can go wrong, ensuring your Kongsberg table keeps running smoothly.

Built to endure, it guarantees stability for years. Kongsberg’s comprehensive service plans and global service teams ensure rapid response, and with a swift installation process, disruption is minimal.

Even when operators approach for inspection, the machine adjusts without halting production. It naturally slows down upon first proximity, then pauses production if the operator gets even closer.

Vibrant LED indicators ensure that machine status is discernible from any angle, at any given moment.

Compliant with top-tier safety regulations and enhanced with the tool guard feature, the Kongsberg Ultimate ensures "contactless" production, reducing any risk of physical contact.

The i-cut Production Console 3.0 interface, complemented by easily accessible buttons, simplifies the user's journey, making operations smoother and more intuitive.

Thanks to the SmartZone™ feature, there's no safety cage restricting access. Operators can easily approach the machine from all sides, making loading and monitoring more convenient than ever.

With a focus on local sourcing, energy efficiency, and reduced waste thanks to features like precision cameras, we're not just meeting sustainability standards, but setting new ones.

Interested in experiencing the future of corrugated cutting? Get in touch with us and have a chat with our industry experts.