Features

Want to talk to a specialist? Just leave your contact info and we'll get back to you.

The innovative carbon fiber traverse of 3,2 meters makes the Kongsberg C uniquely equipped for high speeds and fast acceleration.

Its rigid quality makes it possible to maintain a consistent accuracy on all materials. It also minimizes deflection when carrying heavy tooling or creasing with high down-force.

The Kongsberg C tables can be configured for milling applications ranging from sporadic, light-duty routing to lengthy jobs working with heavy-duty materials – all with record breaking productivity.

The Kongsberg C is the only super-wide finisher with a 3kW continuous duty High-Performance Milling Unit.

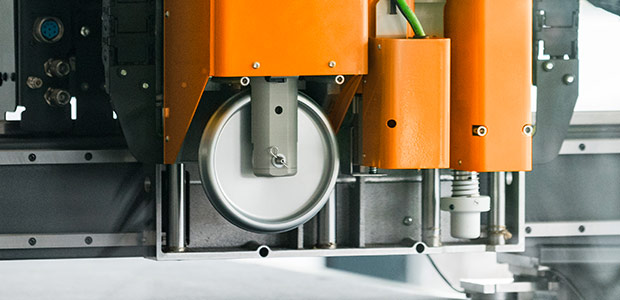

The Heavy Duty Tool Unit offers 500N (110lbs) of down force, sufficient to crease even the most challenging materials at large diameter creasing dimensions (150mm).

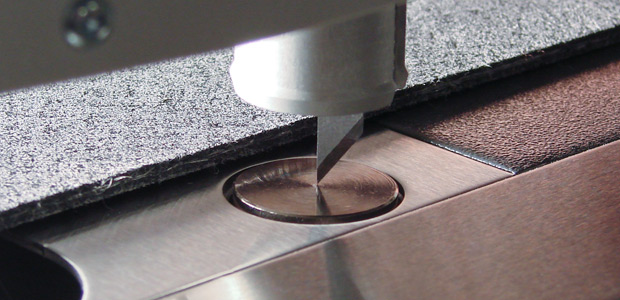

Tool, bit or blade exchange is fast and effortless thanks to the integrated tool tip height sensor. It accurately and automatically calibrates the working depth for different tools and greatly contributes to simple operation.

A complete set of advanced, quick change tool heads provides versatility, making it easy to set up the cutting table to process any material.

The dynamic table mapping procedure provides a real-time update to the exact field conditions.

The precise automatic z-control during cutting and routing, using table-top mapping, guarantees unsurpassed finishing quality.

The workstation is designed with the focus on operator safety and ease of use. It comes standard with an integrated joystick and operator panel. The workstation can be mounted left, right and in the machine front, when no conveyor feed option is installed.

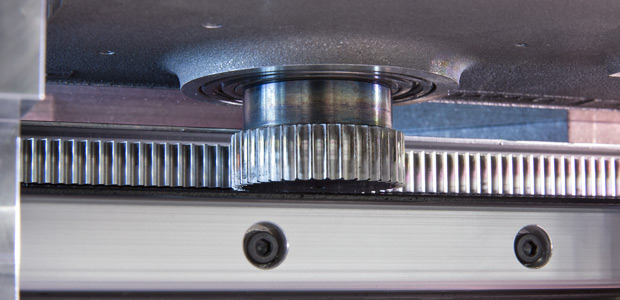

The rack-and-pinion drive system provides speed, durability and the brutal power required to drive through dense, thick materials.

The system offers great dynamic repeatability at heavy workloads.

An additional control panel at the end of the traverse offers easy access for the operator, speeding up production.

The Kongsberg C can be outfitted with a wide-format roll feeder to support heavy-duty rolls of materials like textile, vinyl ... up to 3330mm (131 inch) wide.

The convenient tooling cart makes changing blades, bits and tool inserts very straightforward.

| C20 | C24 | C44 | C60 | C64 | C66 | ||

| Work area | 1680 x 1430 66 x 56 |

1680 x 3200 66 x 126 |

2210 x 3200 87 x 126 |

3210 x 1600 126.37 x 63 |

3210 x 3200 126.37 x 126 |

3210 x 4800 126.37 x 189 |

mm in. |

| Work area, MultiZone production, standard tabletop | n/a |

1680 x 1450 66 x 57 |

2210 x 1450 87 x 57 |

n/a | 3210 x 1600 126 x 63 |

3210 x 2210 126 x 87 |

mm in. |

| Max. material size, w/o conveyor feed | 1740 x 1900 68 x 75 |

1740 x 3700 68 x 146 |

2270 x 3700 89 x 146 |

3330 x 2125 131 x 83½ |

3330 x 3730 131 x 147 |

3330 x 5330 131 x 210 |

mm in. |

| Max. material width, w/ conveyor feed | 1680 66 |

1680 66 |

2210 87 |

3210 126½ |

3210 126½ |

n/a | mm in. |

| Overall dimensions incl. workstation | 3600 x 2300 142 x 91 |

3600 x 3900 142 x 154 |

4100 x 3900 161 x 154 |

5100 x 2320 201 x 91½ |

5100 x 3920 201 x 154½ |

5100 x 5520 201 x 217 |

mm in. |

| Overall dimensions excl. workstation | 2760 x 2300 109 x 91 |

2760 x 3900 109 x 154 |

3260 x 3900 128 x 154 |

4260 x 2320 168 x 91½ |

4260 x 3920 168 x 154½ |

4260 x 5520 168 x 217 |

mm in. |

| Weight | 800 1765 |

600 1325 |

800 1760 |

800 1760 |

1300 2870 |

1750 3960 |

kg lbs |

| Max. speed | 100 1666 66 |

m/min mm/sec IPS |

|||||

| Max. acceleration | 1.72 G | 1.72 G | 1.65 G | 1.57 G | 1.57 G | 1.57 G | |

| Vacuum sections | 4 | 8 | 8 | 4 | 8 | 8 | |

| Traverse clearance (excl. cutting underlay) | 70 2.75 |

mm in. |

|||||

We are here for you! Just leave your contact info and we'll get back to you.