Combining power & precision with industry-leading CNC Tables

When selecting a CNC router for professional use, it's essential to consider various factors that directly impact the machine's performance, versatility, and ease of use.

When selecting a CNC router for professional use, it's essential to consider various factors that directly impact the machine's performance, versatility, and ease of use.

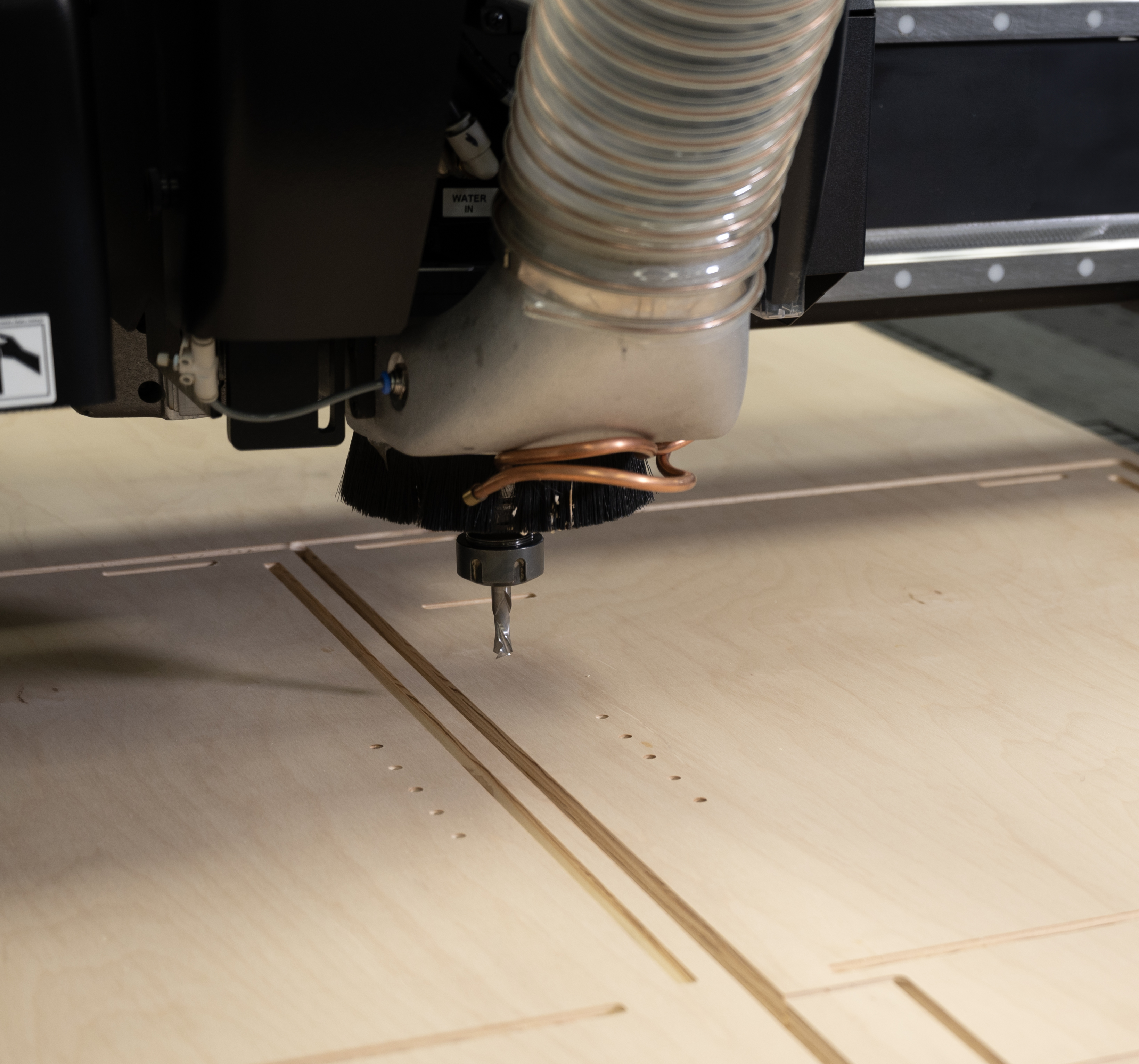

A CNC table is a computer-controlled cutting platform that delivers precise, repeatable results across a range of materials like wood, plastic, metal, and composites. It automates routing, milling, and engraving using digital design files—making it ideal for everything from signage to industrial parts.

Common issues include securing materials properly, choosing the right tools and settings for each job, and managing dust or debris. Learning the software and fine-tuning the machine for consistent performance can also take time.

MultiCam CNC router tables are built for precision, consistency, and ease of use—helping you overcome common CNC challenges. With repeatability down to 1/1000th of an inch, you can count on accurate cuts every time.

Each table is engineered for reliable hold-down, efficient chip management, and compatibility with a wide range of materials. Plus, with customizable options and intuitive control systems, MultiCam makes it easier to tailor your setup to your specific application and skill level—whether you're cutting signage, woodwork, or complex industrial parts.

Compact but capable, the Apex1R is ideal for everyday applications like signage, 2D cutting, and light 3D carving. It's a reliable choice for shops that need consistent performance across a variety of materials, including plastics, woods, and light metals.

Designed for greater flexibility, the Apex3R Evo handles more advanced tasks with enhanced precision and speed. With available accessories like oscillating knives and automatic tool changers, it’s well suited for packaging, foam, insulation, and print-to-cut workflows.

Built for heavy-duty production, the 5000 Series delivers high-speed cutting and exceptional power for demanding jobs. It’s engineered for thick aluminum, large-format composites, and high-throughput environments like marine or aerospace fabrication.

MultiCam CNC router tables are built to cut a wide variety of materials with precision and reliability. From standard substrates like wood, MDF, and plywood to industrial-grade plastics and non-ferrous metals such as aluminum and brass, these tables handle it all with ease.

They’re also well equipped for more advanced and abrasive materials, including fiberglass, ACM cladding, phenolic, and hardened carbon fiber, making them ideal for industries like aerospace, signage, packaging, and marine. No matter the material, MultiCam machines deliver consistent, high-quality results.

All routers CNC tables come loaded with MultiCam’s proprietary, and easy-to-use software, so it’ll be simple to start cutting with extreme precision right away.

MultiCam provides support their global customers with a network of sales, service and process application experts. Your investment in a CNC table is safe!

Do you want more information? Would you like to schedule a demo or request a quote? We are here for you! Just leave your contact info below and we'll get back to you.