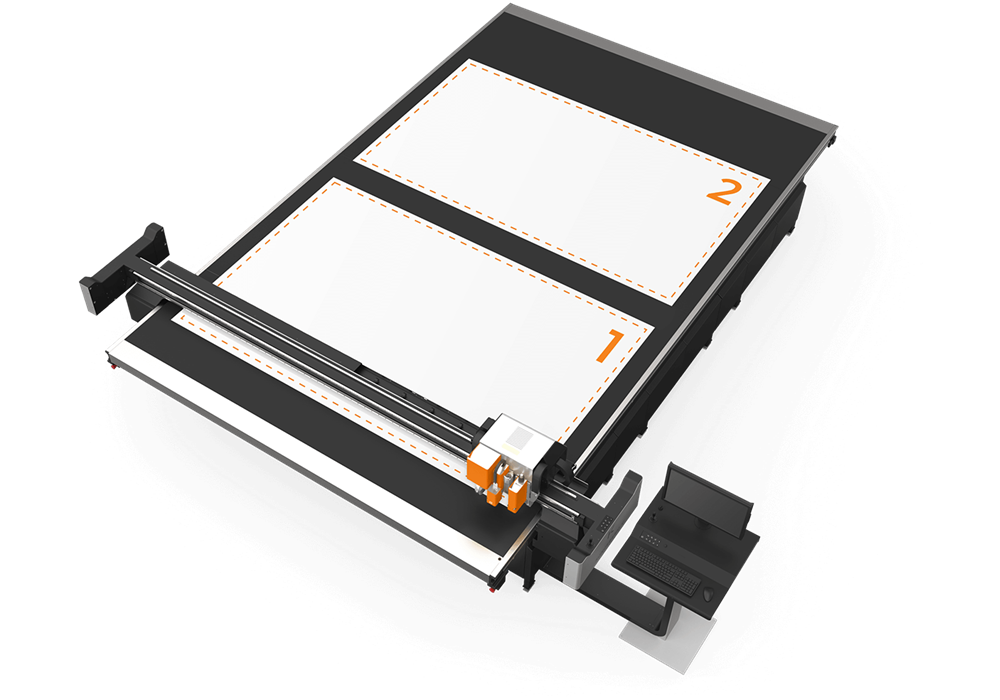

Smart Material Handler

Smart sheet handling that keeps production moving

The Smart Material Handler streamlines sheet flow on Kongsberg tables. It guides loading and offloading so idle time drops and production keeps moving.

Operators stage the next sheet while the current job finishes, and the offload area helps collect finished work smoothly. SMH supports operator-assisted registration with optional Under Side Camera for print-side-down jobs. It fits 2x, 4x and 6x Kongsberg C and Ultimate setups, with an alignment bracket to keep sheets parallel to conveyor movement. The system is rollfeeder ready, which lets teams switch quickly between sheet and roll production.